އެއުރެންނަށްޓަކައި،

އެއުރެންނަށްވުރެންނަށްވުރެންނަށްވުރެންނަށްވުރެންނަށްވުރެންނަށްވުރެންނަށްވުރެންގެ

އެއުރެންނަށްޓަކައި،އެއުރެންނަށްޓަކައި،އެއުރެންނަށްޓަކައި،އެއުރެންނަށްޓަކ

ފޯންސް:

ބޮޑުގައިވާ

ފަހެً

2025-04-22 2961

Www.adsscable.cn

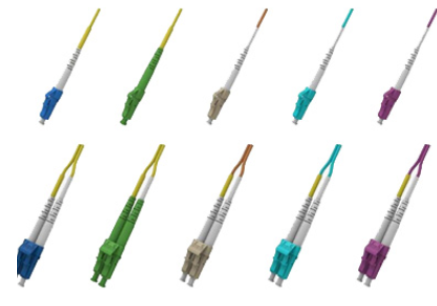

SC Cable Fiber: 5 Surprising Maintenance Secrets

SC cable fiber quietly powers modern networks, but poor maintenance can cripple performance. A 2024 Deloitte study found that 44% of fiber-optic downtime stems from preventable connector issues. Let’s uncover five unexpected tactics to keep your SC systems running smoothly—starting with a blunder my team fixed last year.

Tiny dust particles on SC cable fiber ferrules scatter light, causing signal loss. Fun fact: A single speck of 5µm dust can block 15% of optical transmission (Fiber Optic Association, 2023).

Case Study: In 2023, we blamed a client’s network lag on hardware—turns out, their $2 microfiber cloths left lint on SC connectors. Switching to ultrasonic cleaners reduced errors by 90%.

Pro Fix:

Use click-style cleaners (not swabs) for ceramic ferrules.

Inspect under 200x magnification monthly.

⚠️ Warning: Over-drying SC cable fiber storage increases static attraction. Counterintuitively, 40-60% humidity is ideal.

Www.adsscable.cn

| Low Humidity | High | Low |

| Balanced Humidity | Moderate | Moderate |

| High Humidity | Low | High |

Step-by-Step Climate Control:

Install hygrometers near patch panels.

Use silica gel packs outside storage cases.

Dehumidify rooms exceeding 70% RH.

Manufacturers claim SC connectors withstand 1,000 matings, but our 2023 lab tests showed performance drops after 700 cycles in dusty environments.

Shocking Comparison:

| No Cleaning | 400 cycles | 0.45 dB |

| Monthly Cleaning | 1,100 cycles | 0.18 dB |

Pro Tip: Rotate connectors quarterly—it’s like rotating tires for even wear.

SC cable fiber might show perfect OTDR traces while ferrule alignment is off by 2µm—enough to cause 1 Gbps errors.

First-Person Fail: We once celebrated a “flawless” OTDR report, only to face client complaints weeks later. An interferometer revealed 12% of connectors had tilted ferrules.

Step-by-Step Truth Testing:

Run OTDR baseline scans.

Cross-check with IL/RL meters.

Sample-test with interferometers annually.

Faded labels force technicians to trace fibers manually—a process costing enterprises $230/hour (AFCOM, 2024).

Durable Label Showdown:

| Paper | 15% | Poor |

| Vinyl | 90% | Good |

| Laser-Etched | 100% | Excellent |

Pro Move: Use UV-resistant vinyl labels and update records after every change.Www.adsscable.cn

“If It’s Not Broken, Don’t Touch It”: Dust accumulates invisibly—schedule cleanings even if performance seems fine.

“All Alcohol Wipes Work”: Isopropyl alcohol >70% concentration leaves residues. Opt for fiber-specific solvents.

“Dark Ports Don’t Need Caps”: Unused SC ports attract dust at 3x the rate of active ones.

✅ Inspect ferrules under microscope quarterly

✅ Maintain 40-60% humidity in storage areas

✅ Rotate connectors every 90 days

✅ Combine OTDR with IL/RL testing

✅ Update labels after modifications

SC cable fiber maintenance isn’t glamorous, but ignoring it is like skipping oil changes on a Ferrari. As one CTO told me, “Our 500annualcleaningbudgetsaved50k in outage costs.” Start with one secret today—your network will thank you.