އެއުރެންނަށްޓަކައި،

އެއުރެންނަށްވުރެންނަށްވުރެންނަށްވުރެންނަށްވުރެންނަށްވުރެންނަށްވުރެންނަށްވުރެންގެ

އެއުރެންނަށްޓަކައި،އެއުރެންނަށްޓަކައި،އެއުރެންނަށްޓަކައި،އެއުރެންނަށްޓަކ

ފޯންސް:

ބޮޑުގައިވާ

ފަހެً

2025-09-15 1523

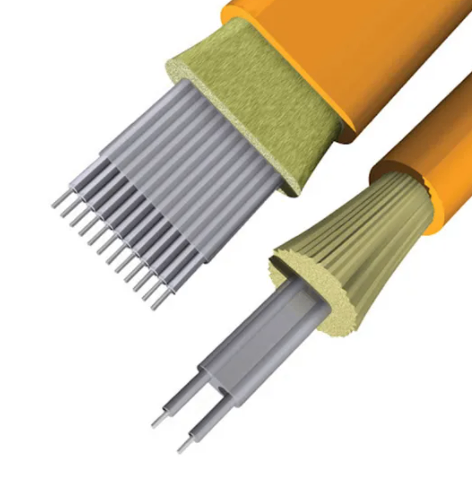

Ribbon indoor flat ފިރް features a revolutionary design that stacks multiple fiber ribbons in a flat, rectangular arrangement rather than the conventional circular configuration. The typical construction includes 12-fiber ribbons coated with UV-cured resin, organized in a stacked matrix, and enclosed in a slim, flat jacket that's often less than 3mm thick. This design provides exceptional flexibility for tight spaces while maintaining excellent protection for the delicate fibers. The flat profile allows for easier routing under carpets, through raised floors, or in ceiling plenums where space is limited but high fiber counts are required.

Ribbon indoor flat ފިރް offers several distinct advantages that make it ideal for modern high-density environments. First, it provides unparalleled space efficiency – a 144-fiber flat cable occupies approximately 40% less space than equivalent round cables. Second, the flat design enables easier handling and installation in confined areas like data center raceways or office conduits. Third, these cables typically feature bend-insensitive fibers that maintain performance even when routed around tight corners. Finally, the ribbon configuration allows for mass fusion splicing, reducing termination time by up to 70% compared to single fiber splicing methods.

Proper installation ensures optimal performance of your ribbon indoor flat ފިރް. Begin with pathway preparation, ensuring surfaces are smooth and free of sharp edges that could damage the flat cable profile. ފަހެً, carefully measure and cut the cable using precision tools, maintaining the required bend radius (typically 20 times the cable thickness). Third, prepare the cable ends using ribbon-specific stripping tools that expose the fiber array without damaging individual fibers. Fourth, perform mass fusion splicing using appropriate equipment, ensuring proper alignment of all fibers simultaneously. Finally, secure the cable in place using flat-specific cable ties that distribute pressure evenly across the cable width.

⚠️ Warning: These installation errors can compromise cable performance

Avoid excessive bending beyond the specified minimum radius, which can cause microcracks in fibers. Never use conventional round cable ties, as they create pressure points that may deform the flat cable structure. Don't attempt to separate individual fibers without proper ribbon splitting tools – this risks damaging adjacent fibers. Always maintain proper polarity when splicing multiple ribbons to prevent connectivity issues. Interestingly, most installation failures occur not during the splicing process but during cable routing, particularly when pulling through congested pathways.

| Parameter | Ribbon Flat Cable | Conventional Round Cable |

|---|---|---|

| Space Efficiency | Excellent (high fiber density) | Moderate (lower density) |

| Installation Flexibility | Superior in tight spaces | Limited by bend radius |

| Splicing Efficiency | High (mass splicing possible) | Low (individual splicing) |

| Pathway Utilization | Optimal for flat raceways | Better for circular conduits |

| Cost per Fiber | Lower at high counts | Higher at high counts |

During a 2024 office tower retrofit, our team deployed ribbon indoor flat ފިރް to replace outdated copper infrastructure. The project required distributing 432 fibers across 36 floors while minimizing disruption to occupied spaces. Using the flat cable design, we achieved a 60% reduction in pathway space requirements compared to traditional round cables. The mass splicing capability allowed us to terminate all fibers in just three days instead of the projected two weeks. Post-installation testing showed consistent performance across all fibers with average insertion loss of 0.28 dB, well within specifications.

Verify cable bend radius compliance throughout the pathway

Inspect for physical damage or deformation monthly

Clean connectors quarterly using approved methods

Document all splicing points and connections

Perform annual insertion loss testingWww.adsscable.cn

Validate polarity maintenance after any changes

Ensure proper strain relief at all termination points

Can ribbon flat cable be used in plenum spaces?

Yes, most ribbon indoor flat ފިރްs are available with plenum-rated jackets that meet NEC requirements for air handling spaces.

How many fibers can a typical flat ribbon cable contain?

Standard configurations range from 12 to 144 fibers, with some specialty cables accommodating up to 288 fibers.

Is special equipment needed for termination?

Yes, ribbon cables require specific stripping tools and mass fusion splicers for proper termination.

Can individual fibers be accessed without cutting the entire ribbon?

Yes, specialized tools allow for accessing individual fibers while maintaining ribbon integrity for remaining fibers.

Are these cables compatible with existing connectors?

Absolutely, they use standard LC, SC, or MTP connectors depending on configuration and application requirements.

Ribbon indoor flat ފިރް technology continues to evolve, offering increasingly sophisticated solutions for high-density environments. By following these guidelines and best practices, you can ensure reliable performance and future-proof your optical infrastructure.